Features

Spring loaded, With soft seat Screwed female BSP parallel threads as per BS-21

Test Pressure

1. Body : 300 Psi g (Hyd.)

2. Seat : 150 Psi g (Hyd.), 100 Psi g (Air)

In 1982, Atam Valves Pvt. Ltd. started production of valves under brand name 'ATAM' and FEBI Valves Pvt. Ltd. entered the market with Ball Valves in 1992-93. The products were very well received in the market The product line consists of a complete range of Bushings, Valves and Boiler Mountings. The Company can undertake designing and manufacturing of valves as per the customer's design & specifications.

Bushing : Brass, Gun-Metal & Bronze bushings up to 300mm OD and 600mm length.

Valves & Boiler Mountings: Brass, Bronze, Cast Iron, Cast Steel, Forged Steel & Stainless Steel Investment Casting valves and Boiler Mountings viz. Gate Valves, Globe Valves, Check Valves, Pressure-Reducing Valves, Steam Traps, Gauge Glass Cocks, Strainers, Safety Valves (Single Post/Double Post), Ball Valves, Steam Stop Valves, Parallel Slide Blow down Valves, Fusible Plugs, Combined Feed Check Valves, Injectors, Sight Glass, Moisture Separators etc.

Spring loaded, With soft seat Screwed female BSP parallel threads as per BS-21

1. Body : 300 Psi g (Hyd.)

2. Seat : 150 Psi g (Hyd.), 100 Psi g (Air)

Three Piece Design, Lever Operated (Blow Out Proof Stem), Renewable Seat, SS Trim Flanged End to BS-10 Table �F� (Undrilled)

1. Body 300 Psi g (Hyd.)

2. Seat 200 Psi g (Hyd.)

3. Seat 150 Psi g (Steam)

Two Piece Design, Lever Operated (Blow Out Proof Stem), Renewable Seat, SS Trim Screwed Female Parallel Threads as per IS-554 Product Standard : IS-9890

1. Body 300 Psi g (Hyd.)

2. Seat 220 Psi g (Hyd.)

Horizontal Type, Side Inlet Side Outlet, SS working part Screwed Female BSP Parallel Threads to (BS-21)

1. Body : 300 Psi g (Hyd.)

2. Max. Working Pressure : 150 Psi g

3. Max. Working Temp. : 220C

Two Piece Design, Full Bore, Renewable Seat, SS 304 Trim Screwed Female Ends to BSP/BSPT/NPT/ Socket welded ends to ASME B16.11

1. Seat 700 Psi g (Hyd.)

2. Seat 150 Psi g (Steam)

Two Piece Design, Full Bore, Renewable Seat, SS 316 Trim Screwed Female Ends to BSP/BSPT/NPT/Socket welded ends to ASME B16.11

1. Seat 700 Psi g (Hyd.)

2. Seat 150 Psi g (Steam)

Two Piece Design, Lever Operated (Blow Out Proof Stem), Renewable Seat Screwed Female BSP Parallel Threads (BS-21)

1. Body 550 Psi g (Hyd.)

2. Seat 400 Psi g (Hyd.), 100 Psi g (Steam)

Two Piece Design, Full Bore, Renewable Seat, SS 316 Trim Flanges as per ANSI B16.5 Class-150 (Drilled)

1. BS-17292/API-6D

1. Body 30 Bar (Hyd.)

2. Seat 22 Bar (Hyd.)

1. BSEN-12266-1/ API-598

Two Piece Design, Full Bore, Lever Operated (Blow Out Proof Stem), Renewable Seat, SS Trim Flanges as per ANSI B16.5 Class-150 (Drilled)

1. BS-17292/ API-6D

1. Body 30 Bar (Hyd.)

2. Seat 22 Bar (Hyd.)

1. API-598/ BSEN-12266-1

Two Piece Design, Full Bore, Renewable Seat, SS 316 Trim Flanges as per ANSI B16.5 Class-150 (Drilled)

1. BS-17292/API-6D

1. Body 30 Bar (Hyd.)

2. Seat 22 Bar (Hyd.)

1. BSEN-12266-1/ API-598

Three Piece Design, Full Bore, Renewable Seat, SS 304 Trim Flanges as per ANSI b16.5 Class-150 (Drilled)

1. BS-17292/ API-6D

1. Body 30 Bar (Hyd.)

2. Seat 22 Bar (Hyd.)

1. API-598/ 12266-1

One Piece Design, Reduced Bore, Renewable Seat, SS 304 Trim Screwed Female BSP Parallel Threads (BS-21)

1. Body 1000 Psi g (Hyd.)

One Piece Design, Reduced Bore, Renewable Seat, SS 316 Trim Screwed Female Ends to BSP Threads (BS-21)

1. 1000 Psi g (Hyd.)

Three Piece Design, Full Bore, Renewable Seat, SS 304 Trim Screwed Female Ends BSP/BSPT/NPT/ Socket welded ends as per ASME-B16.11

1. Body 178

2. Bar (Hyd.)

3. Seat 76 Bar (Hyd.)

Three Piece Design, Full Bore, Renewable Seat, SS 316 Trim Screwed Female Ends BSP/BSPT/NPT/ Socket welded ends as per ASME-B16.11

1. Body 178 Bar

2. Seat 76 Bar.

Full Bore, Three Piece Design, Renewable Seat, SS Trim Screwed Female Ends BSP/BSPT/NPT/ Socket welded ends as per ASME B16.11

1. Body 178 Bar

2. Seat 76 Bar.

Three Piece Design, Full Bore, Renewable Seat, SS Trim Flanges as per ASME B16.5 Class 150 (Drilled)

1. BS-17292

1. Body 30 Bar (Hyd.)

2. Seat 22 Bar (Hyd.)

1. BSEN-12266-1

Two Piece Design, Fire Safe Design, Renewable Seat, SS Trim Flanges as per ASME B16.5 Class 150-(Drilled)

1. API-6D/ EN-17292

1. Body 30 Bar (Hyd.)

2. Seat 22 Bar (Hyd.)

1. BSEN-12266-1

Full Bore, Two Piece Design, Renewable Seat, SS Trim, Mix End Inlet Screwed Female & Outlet Screwed Male BSP Parallel Threads (BS-21)

1. Body 500 Psi g (Hyd.)

2. Seat 250 Psi g (Hyd.) 100 Psi g (Air)

Two Piece Design, Lever Operated (Blow Out Proof Stem), Renewable Seat, SS Trim Flanged End to BS-10 Table �D� (Undrilled)

1. Body 348 Psi g (Hyd.)

2. Seat 255 Psi g (Hyd.)

3. 150 Psi g (Steam)

Two Piece Design, Full Bore, Lever Operated (Blow Out Proof Stem), Renewable Seat, SS Trim Screwed Female BSP Parallel Threads (BS-21)

1. Body 500 Psi g (Hyd.)

2. Seat 250 Psi g (Hyd.)

3. 150 Psi g (Steam)

Two Piece Design, Full Bore, Lever Operated (Blow Out Proof Stem), Renewable Seat, SS Trim Screwed Female BSP Parallel Threads (BS-21)

1. Body 500 Psi g (Hyd.)

2. Seat 250 Psi g (Hyd.)

3. 150 Psi g (Steam)

Wafer Type, Without Lugs, Integrally Moulded Linear Seat Suitable for Insertion between Flanges as per ANSI B 16.1 Cl-125, DIN ND-10 & BS-10 Table�E�

1.IS-13095

1. Body : 230 Psi g (Hyd.)

2. Seat : 150 Psi g (Hyd.)

Wafer Type, Without Lugs, Renewable Linear Seat, EPDM Linear Suitable for Insertion between Flanges as per ANSI B 16.1 CL-125, DIN ND-10 & BS-10 Table�E�

1.IS-13095

1. Body : 300 Psi g (Hyd.)

2. Seat : 200 Psi g (Hyd.)

Wafer Type, Without Lugs, Renewable Linear Seat, EPDM Linear Suitable for Insertion between Flanges as per ANSI B 16.1 Cl-125, DIN ND-10 & BS-10 Table

1.IS-13095

1. Body : 300 Psi g (Hyd.)

2. Seat : 200 Psi g (Hyd.)

Wafer Type, Without Lugs, Integrally Moulded Linear Seat Suitable for Insertion between Flanges as per ANSI B 16.1 Cl-125, DIN ND-10 & BS-10 Table

1.IS-13095

1. Body : 230 Psi g (Hyd.)

2. Seat : 150 Psi g (Hyd.)

Wafer Type, Without Lugs, Renewable Linear Seat, EPDM Linear Suitable for Insertion between Flanges as per ANSI B 16.1 Cl-125, DIN ND-10 & BS-10 Table

1.BSEN-593

1. Body : 300 Psi g (Hyd.)

2. Seat : 200 Psi g (Hyd.)

Single Piece Design , Renewable Seat & Disc Flanged Ends as per BSEN 1092-2 (PN-16)

1. Body : 24kg/cm2 Hyd

2. Seat : 17.6 kg/cm2 Hyd

3. B.O.P. : 13kg/cm2 (Steam)

4. Max. working temp. : 220�C

Bolted Bonnet, O/S Screw & Yoke Type, Rising Stem, Straight/Curved Inlet, With Inspection Branch, Renewable Seat & Disc, SS Trim Flanges as per BS-10 Table FF (Undrilled)

1. 300 Psi g (Hyd.)

2. Max. B.O.P. : 150 Psi g (Steam)

3. Max. Working Temp. : 220C

Bolted Bonnet, O/S Screw & Yoke Type, Rising Stem, Straight Inlet/Curved Inlet, Without Inspection Branch,Renewable Seat & Disc, SS Trim Flanges as per BS-10 Table FF (Undrilled)

1. 300 Psi g (Hyd.)

2. Max. B.O.P. : 150 Psi g

3. Max. Working Temp. : 220�C

Bolted Cover, Renewable Seat, SS Trim Flanges as per ASME B16.5, Class-300 RF (Drilled)

1. BS-1868

1. Body : 76 Bar (Hyd.)

2. Seat : 56 Bar (Hyd.)

1. BSEN-12266-1

Bolted Cover, Renewable Seat, SS 304 Trim Flanges as per ASME B16.5, Class-600 RF (Drilled)

1. BS-1868

1. Body : 153 Bar (Hyd.)

2. Seat : 112 Bar (Hyd.)

1. BSEN-12266-1

Bolted Cover, Renewable Seat, SS Trim Flanges as per ASME B16.5, Class-600 RF (Drilled)

1. BS-1868

1. Body : 153 Bar (Hyd.)

2. Seat : 112 Bar (Hyd.)

1. BSEN-12266-1

Bolted Cover, Renewable Seat, SS 316 Trim Flanges as per ASME B16.5, Class-300 RF (Drilled)

1. BS-1868

1. Body : 76 Bar (Hyd.)

2. Seat : 55 Bar (Hyd.)

1. BSEN-12266-1

Bolted Cover, Renewable Seat, SS 304 Trim Flanges as per ASME B16.5, Class-300 RF (Drilled)

1. BS-1868

1. Body : 76 Bar (Hyd.)

2. Seat : 55 Bar (Hyd.)

1. BSEN-12266-1

Bolted Cover, Renewable Seat, SS Trim Flanges as per ASME B16.5, Class-150 RF (Drilled)

1. BS-1868

1. Body : 76 Bar (Hyd.)

2. Seat : 55 Bar (Hyd.)

1. BSEN-12266-1

Bolted Cover, Renewable Seat, SS 304 Trim Flanges as per ASME B16.5, Class-150 RF (Drilled)

1. BS-1868

1. Body : 30 Bar (Hyd.)

2. Seat : 22 Bar (Hyd.)

1. BSEN-12266-1

Bolted Cover, Renewable Seat, SS Trim Flanges as per ASME B16.5, Class-150 RF (Drilled)

1. BS-1868

1. Body : 30 Bar (Hyd.)

2. Seat : 22 Bar (Hyd.)

1. BSEN-12266-1

Bolted Cover, Renewable Seat & Disc, SS Trim Flanged Ends as per BSEN 1092-2 (PN-16)

1. Body : 24kg/cm2 (348 Psi g) Hyd.

2. Seat : 17.6kg/cm2 (255 Psi g) Hyd.

Bolted Cover, Renewable Seat & Disc, SS Trim Flanged Ends as per BSEN 1092-2, (PN-16)

1. Body : 24kg/cm2 (348 Psi g) Hyd.

2. Seat : 17.6kg/cm2 (255 Psi g) Hyd.

Reduced Bore, Bolted Cover, Renewable Seat & Disc, SS Trim Socket Welded Ends as Per ASME B-16.11

1.API-602/ EN-15761

1. Body 207 Bar (Hyd.)

2. Seat 152 Bar (Hyd.)

1.API-598/ BSEN-1266-1

Reduced Bore, Bolted Cover, Renewable Seat & Disc, SS 316 Trim Socket Welded Ends as Per ASME B-16.11

1.API-602/ EN-15761

1. Body 207 Bar (Hyd.)

2. Seat 152 Bar (Hyd.)

1.API-598/ BSEN-1266-1

Reduced Bore, Bolted Cover, Renewable Seat & Disc, SS 304 Trim Socket Welded Ends as Per ASME B-16.11

1.API-602/ EN-15761

1. Body 207 Bar (Hyd.)

2. Seat 152 Bar (Hyd.)

1.API-598/ BSEN-1266-1

Reduced Bore, Bolted Cover, Renewable Seat & Disc, SS Trim Screwed Female NPT Threads as per ASME B1.20.1 .

1.API-602/ EN-15761

1. Body 207 Bar (Hyd.)

2. Seat 152 Bar (Hyd.)

1.API-598/ BSEN-1266-1

Standard Bore, Bolted Cover, Renewable Disc, SS Trim Socket Welded Ends as per ASME b-16.11

1.API-602/ EN-15761

1. Body : 384 Bar (Hyd.)

2. Seat : 281 Bar (Hyd.)

1.BSEN-12266-1

Standard Bore, Bolted Cover, Renewable Disc, SS 304 Trim Socket Welded Ends as per ASME b-16.11

1.API-602/ EN-15761

1. Body : 384 Bar (Hyd.)

2. Seat : 281 Bar (Hyd.)

1.BSEN-12266-1

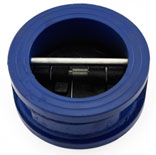

Wafer type, Spring loaded, Resilient seated (EPDM/Nitrile)Clamping between flanges as per ASME ANSI B 16.1, Class 125

1.API-594

1. Body : 20.7 Bar (Hyd.)

2. Seat : 15.2 Bar (Hyd.)

1.API-598

Standard Bore, Bolted Cover, Renewable Disc, SS 316 Trim Socket Welded Ends as per ASME b-16.11

1.API-602/ EN-15761

1. Body : 153 Bar (Hyd.)

2. Seat : 112 Bar (Hyd.)

1.API-598/ BSEN-12266-1

Standard Bore, Bolted Cover, Renewable Seat & Disc, SS Trim Flanges as per ASME B 16.5 CL-600 R.F. (Drilled)

1.602/EN-15761

1. Body : 153 Bar (Hyd.)

2. Seat : 112 Bar (Hyd.)

1.API-598/ BSEN-12266-1

Screwed in bonnet / Bolted Bonnet, Yoke type, Outside screw,Rising stem, Straight/ Right Angle Pattern Flanged ends as per BS-10, Table-H (Undrilled)

1. Body : 500 Psi g (Hyd.)

2. Max. Steam Working Pressure : 250 Psi g

3. Max. Working Temp. : 220�C

Outside Screw, Yoke Type, Screwed in bonnet / Bolted Bonnet, Rising Stem, Renewable Seat & Disc, SS Trim Screwed Female BSP Taper Threads (BS-21)

1. 500 Psi g (Hyd.)

2. Max. Steam working pressure : 250 Psi g

3. Max. working temp. : 220�C

Outside Screw, Yoke Type, Screwed in bonnet / Bolted Bonnet, Rising Stem, Renewable Seat & Disc, SS Trim Screwed Female BSP Taper Threads (BS-21)

1. 500 Psi g (Hyd.)

2. Max. Steam working pressure : 250 Psi g

3. Max. working temp. : 220�C

Flanges as per BS-10 Table FF (Undrilled)

1. 300 Psi g (Hyd.)

2. Max. B.O.P. : 150 Psi g

Straight Inlet, Bolted Bonnet, Outside Screw, Yoke Type, Rising Stem, SS Trim Flanges as per BS-10 Table �J� FF (Undrilled)

1. Body : 700 Psi g (Hyd.)

2. Max. B.O.P. : 350 Psi g

Screwed in Cover, Renewable Seat & Disc, SS Trim Flanges as per BS-10 Table FF (Undrilled)

1. 500 Psi g (Hyd.)

2. Max. Steam working pressure : 250 Psi g

Screwed in Cover, Renewable Seat & Disc, SS Trim Screwed Female BSP Taper Threads (BS-21)

1. 500 Psi g (Hyd.)

2. Max. Steam working Pressure : 250 Psi g

Bolted Cover, Renewable Seat, SS Trim Flanged End as per BSEN 1092-1, PN-40, RF

1.BS-13709 (BS-5160)

1. Body : 60 Bar (Hyd.)

2. Seat : 40 Bar (Hyd.)

1.BS-12266, Part-1

Screwed in cover, Guided disc Screwed female parallel threads to IS 554 Product Standard : IS-778

1. Body : 2.4 MPa (Hyd.)

2. Seat : 1.6 MPa (Hyd.)

3. Max. Working Pressure : 1.6 MPa (Hyd.)

4. Max. Working Temp. : Upto 45C

1.IS-778

Spring loaded, Vertical type, Integral seat Screwed female BSP parallel threads as per BS-21

1. MSS SP-80

1. Body : 300 Psi g (Hyd.)

2. Seat : 200 Psi g (Hyd.), 100 Psi g (Air)

Screwed in cover Screwed female BSP parallel threads to BS-21

1. BS 5154

1. Body : 450 Psi g (Hyd.)

2. Seat : 320 Psi g (Hyd.)

3. Max. Working Pressure : 290 Psi g (Hyd.)

4. Max. Working Temp. : 200C

Wafer Type, Renewable Seat Suitable for Insertion between PN-10/PN-16/Class-150/BS-10 Table-E/F

1. Body : 24 Bar (Hyd.)

2. Seat : 17.6 Bar (Hyd.)

S.S. trim, Screwed in cover Screwed female BSP parallel threads to BS-21

1. BS 5154

1. Body : 450 Psi g (Hyd.)

2. Seat : 320 Psi g (Hyd.)

3. Max. Working Pressure : 290 Psi g (Hyd.)

4. Max. Working Temp. : 200C

Reduced Bore, Bolted Cover, Renewable Seat & Disc, SS 316 Trim Socket Welded Ends as Per ASME B-16.11

1. API-602/ EN-15761

1. Body 207 Bar (Hyd.)

2. Seat 152 Bar (Hyd.)

1. API-598/ BSEN-1266-1

Reduced Bore, Bolted Cover, Renewable Seat & Disc, SS 304 Trim Socket Welded Ends as Per ASME B-16.11

1. API-602/ EN-15761

1. Body 207 Bar (Hyd.)

2. Seat 152 Bar (Hyd.)

1. API-598/ BSEN-1266-1

Screwed in Cover Metallic or Rubber Seat, Integral Seat, Cu-Alloy Trim Flanges as per IS-778 Class-2 FF (Undrilled)

1.IS-778

1. Body 2.4 MPa (Hyd.)

2. Seat 1.6 MPa (Hyd.)

3. Max. Working Pressure : 1.6 MPa (Hyd.)

4. Max. Working Temp. : Upto 45C

1. IS-778

Screwed in Cover Metallic or Rubber Seat, Integral Seat, Cu-Alloy Trim Flanges as per IS-778 Class-1 FF (Undrilled)

1.IS-778

1. Body 1.5 MPa (Hyd.)

2. Seat 1.0 MPa (Hyd.)

3. Max. Working Pressure : 1.0 MPa (Hyd.)

4. Max. Working Temp. : Upto 45C

1. IS-778

Screwed in cover, Guided disc Screwed female parallel threads as per IS 554

1. Body 1.5 MPa (Hyd.)

2. Seat 1.0 MPa (Hyd.)

3. Max. Working Pressure : 1.0 MPa (Hyd.)

4. Max. Working Temp. : Upto 45C

1. IS-778

Bolted Cover, Renewable Seat & Disc, SS Trim Flanged Ends as per BSEN 1092-2 (PN-10)

1. Body : 16kg/cm2 (230 Psi g) Hyd

2. Seat : 10kg/cm2 (142 Psi g) Hyd

Vertical Lift, Metallic or Rubber Seat, Integral Seat, Cu-Alloy Trim Screwed Female Threads to IS 554 (Parallel)

1. Body 1.5 MPa (Hyd.)

2. Seat 1.0 MPa (Hyd.)

3. Working Temperature : upto to 45C

Vertical Lift, Renewable Seat & Disc, SS Trim Screwed Female BSP Parallel Threads (BS-21)

1. Body 450 Psi g (Hyd.)

2. Seat 320 Psi g (Hyd.)

Screwed in cover, Integral Seat

1. Body : 24 Bar g (Hyd.)

2. Seat : 17.6 Bar g (Hyd.)

Screwed in Cover, Integral Seat, Metallic or Rubber Disc, Cu-Alloy Flanged Ends to BS-10 Table (Undrilled)

1. Body 348 Psi g (Hyd.)

2. Seat 255 Psi g (Hyd.)

Screwed on Cover, Renewable Seat & Disc, SS Trim Flanged Ends to BS-10 Table Undrilled

1. Body 450 Psi g (Hyd.)

2. Seat 320 Psi g (Hyd.)

Screwed in Cover, Integral Seat, Cu-Alloy Trim Screwed Female BSP Parallel Threads (BS-21)

1. Body : 300 Psi g (Hyd.)

2. Seat : 150 Psi g (Hyd.)

Union Cover ,S.S. trim, Renewable seat & disc Screwed female BSP parallel threads to BS-21

1. BS 5154

1. Body : 450 Psi g (Hyd.)

2. Seat : 320 Psi g (Hyd.)

Screwed in cover, Integral seat with Teflon disc Screwed female BSP parallel threads to BS-21

1. BS 5154

1. Body : 348 Psi g (Hyd.)

2. Seat : 255 Psi g (Hyd.), 100 Psi g (Air)

3. Max. Working Pressure : 232 Psi g (Hyd.)

4. Max. Working Temp. : 200C

Screwed in cover, Integral seat, Angle pattern, Screwed female BSP parallel threads as per BS-21

1. Body : 348 Psig (Hyd.)

2. Seat : 232 Psig (Hyd.)

3. Max. Working Temp. : 200C

Screwed in cover, Integral seat, Vertical lift, Right angle pattern Screwed male BSP parallel threads as per BS-21

1. Body : 500 Psi g (Hyd.)

2. Seat : 250 Psi g (Hyd.)

Screwed in cover, With Teflon or Rubber disc Screwed female BSP parallel threads to BS-21

1.BS 5154

1. Body : 350 Psi g (Hyd.)

2. Seat : 260 Psi g (Hyd.)

3. Max. Working Pressure : 235 Psi g (Hyd.)

4. Max. Working Temp. : 200C

Bolted Bonnet, Inside Screw, Non-Rising stem Flanged ends as per IS-1538 (Drilled), Table-4

1. IS-14846

1. Body : 2.4 MPa (Hyd.)

2. Seat : 1.6 MPa (Hyd.)

1. IS-14846

Bolted Bonnet Inside Screw, Non-Rising Stem, Renewable Seat, Solid Wedge Flanged ends as per IS-1538 Table-4

1. IS-14846

1. Body 1.5 MPa (Hyd.)

2. Seat 1.0 MPa (Hyd.)

1. IS-14846

Screwed in Cover, Renewable Seat & Disc, SS Trim Screwed Female BSP Taper Threads (BS-21)

1. Body : 500 Psi g (Hyd.)

2. Max. B.O.P. : 250 Psi g

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat & Flat Disc, SS Trim Straight, Right Angle Pattern, Flanged Ends as per BSEN-1092-1 PN-40 RF (Drilled)

1. Body : 60 Bar (Hyd.)

2. Seat : 40 Bar (Hyd.)

Non-Return valve, With swing type disc Suitable for insertion between Flanges as per ANSI B16.1 CL-125, DIN ND-10

1. Body : 348 Psi g (Hyd.)

2. Seat : 255 Psi g (Hyd.)

Screwed in Cover, Renewable Seat & Disc, SS Trim Flanges as per BS-10 Table 'H' FF (Undrilled)

1. Body : 500 Psi g (Hyd.)

2. Max. B.O.P. : 250 Psi g

Bolted Cover, Renewable Seat & Disc Flanged as per IS-1538 Table-4

1. IS-5312 Part-1

1. Body � 1.5 MPa (Hyd.)

2. Seat � 1.0 MPa (Hyd.)

Bolted Cover, Renewable disc & seat ring Flanged as per IS 1538 (Drilled) Table-4, PN-1.6

1. IS 5312 (Part1)

1. Body : 2.4 MPa (Hyd.)

2. Seat : 1.6 MPa (Hyd.)

Bolted Bonnet, Outside Screw & Yoke Type, Rising Stem with Backseat Arrangement, Renewable Seat & Disc, SS Trim Flanges as per BSEN 1092-2 RF (PN-16)

1. Body : 24kg/cm2 (348 Psi g) Hyd.

2. Seat : 17.6kg/cm2 (255 Psi g) Hyd.

Bolted Cover, Renewable disc & seat ring Flanged as per IS 1538 (Drilled) Table-4, PN-1.6

1. IS 5312 (Part1)

1. Body : 2.4 MPa (Hyd.)

2. Seat : 1.6 MPa (Hyd.)

Bolted Cover, Renewable Seat & Disc Flanged as per IS-1538 Table-4

1. IS-5312 Part-1

1. Body 1.5 MPa (Hyd.)

2. Seat 1.0 MPa (Hyd.)

SPressure Gauge Cock Fitted with Pressure Gauge Coupling Nut & Tail Pipe Screwed Female BSP Taper Threads (BS-21)

1. Body : 500 Psi g (Hyd.)

2. Max. BOP Working Pressure : 250 Psi g (Steam)

3. Max. Working Temp. : 220�C

With Bend threaded M20 x 1.5 connection Screwed ends BSP taper threads to BS-21

1. Body : 500 Psi g (Hyd.)

2. Max. BOP Working Pressure : 250 Psi g (Steam)

3. Max. Working Temp. : 220�C

1. Body : 500 Psi g (Hyd.)

2. Max. BOP Working Pressure : 250 Psi g

One Piece design Screwed Male BSP Taper Threads (BS-21)

1. Body : 500 Psi g (Hyd.)

2. Max. BOP Working Pressure : 250 Psi g

Two Piece Design Screwed Male BSP Taper Threads(BS-21)

1. Body : 500 Psi g (Hyd.)

2. Max. Steam working pressure : 250 psi g

Fitted with Taper Plug in a Tapper Seated Body Screwed Female BSP Parallel Threads (BS-21)

1. Body 200 Psi g (Hyd.)

2. Seat 100 Psi g (Hyd.)

Gland Packed Fitted with Taper Plug in a Tapper Seated Body Flanged Ends to BS-10 Table (Undrilled)

1. Body 300 Psi g (Hyd.)

2. Seat 150 Psi g (Hyd.)

Fitted with Taper Plug in a Tapper Seated Body Flanged Ends to BS-10 Table (Undrilled)

1. Body 300 Psi g (Hyd.)

2. Seat 150 Psi g (Hyd.)

Gland Packed Fitted with Taper Plug in a Tapper Seated Body Screwed Female BSP Parallel Threads (BS-21)

1. Body 300 Psi g (Hyd.)

2. Seat 150 Psi g (Hyd.)

Vertical Lift, Metallic Strainer without Spring, Integral Metallic Disc Screwed Female BSP Parallel Threads (BS-21)

1. Body 435 Psi g (Hyd.)

2. Seat 320 Psi g (Hyd.)

Vertical lift, Rubber seat with metallic strainer, Integral seat, Cu-Alloy trim Screwed female BSP parallel threads as per BS-21

1. Body 435 Psi g (Hyd.)

2. Seat 320 Psi g (Hyd.)

3. Max. Working Pressure : 290 Psi g (Hyd.)

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid Wedge, SS 316 Trim Screwed Female NPT Threads as per ASME B1.20.1

1. API-602/ EN-15761

1. Body : 207 Bar (Hyd.)

2. SSeat : 152 Bar (Hyd.)

1. API-598/ BSEN-12266-1

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid Wedge, SS Trim Socket Welded Ends as Per ASME B-16.11

1. API-602/ EN-15761

1. Body 207 Bar (Hyd.)

2. Seat 152 Bar (Hyd.)

1. API-598/ BSEN-12266-1

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid Wedge, SS Trim Screwed Female NPT Threads as per ASME B1.20.1

1. API-602/ EN-15761

1. Body : 207 Bar (Hyd.)

2. Seat : 152 Bar (Hyd.)

1. API-598/ BSEN-12266-1

Standard Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Solid Wedge, SS 316 Trim Socket Welded Ends as per Asme B-16.11

1. API-602/ EN-15761

1. Body : 384 Bar (Hyd.)

2. Seat : 281 Bar (Hyd.)

1. BSEN-12266-1

Standard Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Solid Wedge, SS 304 Trim Socket Welded Ends as per Asme B-16.11

1. API-602/ EN-15761

1. Body : 384 Bar (Hyd.)

2. Seat : 281 Bar (Hyd.)

1. BSEN-12266-1

Standard Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Solid Wedge, SS Trim Socket Welded Ends as per Asme B-16.11

1. API-602/ EN-15761

1. Body : 384 Bar (Hyd.)

2. Seat : 281 Bar (Hyd.)

1. BSEN-12266-1

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid Wedge, SS Trim Flanged ends as per IS-1538 Table-4

1. IS-14846/BSEN-1171

1. Body 2.4 MPa (Hyd.)

2. Seat 1.6 MPa (Hyd.)

1. BESN-12266 Part-1

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid Wedge Flanges as per IS-1538 PN-1.0 FF (Drilled)

1. IS-14846/BSEN-1171

1. Body : 1.5 MPa (Hyd.)

2. Seat : 1.0 MPa (Hyd.)

1. BESN-12266 Part-1

Standard Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, SS Trim Flanges as per ASME B 16.5 CL-600 R.F. (Drilled)

1. 602/EN-15761

1. Body : 153 Bar (Hyd.)

2. Seat : 112 Bar (Hyd.)

1. BAPI-598/ BSEN-12266-1

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid Wedge, SS 304 Trim Screwed Female NPT Threads as per ASME B1.20.1

1. API-602/ EN-15761

1. Body : 207 Bar (Hyd.)

2. Seat : 152 Bar (Hyd.)

1. API-598/ BSEN-12266-1

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid or Flexible Wedge , SS 316 Trim Flanges as per ASME B16.5, CLass-600 RF (Drilled)

1. BS-1414/API-600

1. Body : 153 Bar (Hyd.)

2. Seat : 112 Bar (Hyd.)

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid or Flexible Wedge , SS 304 Trim Flanges as per ASME B16.5, CLass-600 RF (Drilled)

1.BS-1414/API-600

1. Body : 153 Bar (Hyd.)

2. Seat : 112 Bar (Hyd.)

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid or Flexible Wedge , SS 316 Trim Flanges as per ASME B16.5, CLass-300 RF (Drilled)

1. BS-1414/API-600

1. Body : 76 Bar (Hyd.)

2. Seat : 55 Bar (Hyd.)

1. BSEN-12266-1/ API-598

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid or Flexible Wedge , SS 304 Trim Flanges as per ASME B16.5, CLass-600 RF (Drilled)

1. BS-1414/API-600

1. Body : 153 Bar (Hyd.)

2. Seat : 112 Bar (Hyd.)

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid or Flexible Wedge , SS 316 Trim Flanges as per ASME B16.5, CLass-300 RF (Drilled)

1. BS-1414/API-600

1. Body : 76 Bar (Hyd.)

2. Seat : 55 Bar (Hyd.)

1.BSEN-12266-1/ API-598

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid or Flexible Wedge , SS 304 Trim Flanges as per ASME B16.5, CLass-300 RF (Drilled)

1. BS-1414/API-600

1. Body : 76 Bar (Hyd.)

2. Seat : 55 Bar (Hyd.)

1.BSEN-12266-1/ API-598

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid or Flexible Wedge , SS 316 Trim. Flanges as per ASME B16.5, CLass-150 RF (Drilled)

1. BS-1414/API-600

1. Body : 30 Bar (Hyd.)

2. Seat : 22 Bar (Hyd.)

1.BSEN 12266-1/ API-598

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid or Flexible Wedge , SS Trim Flanges as per ASME B16.5, CLass-600 RF (Drilled)

1. BS-1414/API-600

1. Body : 153 Bar (Hyd.)

2. Seat : 112 Bar (Hyd.)

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid or Flexible Wedge , SS Trim Flanges as per ASME B16.5, CLass-300 RF (Drilled)

1.BS-1414/API-600

1. Body : 76 Bar (Hyd.)

2. Seat : 55 Bar (Hyd.)

BSEN-12266-1/ API-598

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid or Flexible Wedge , SS 304 Trim.Flanges as per ASME B16.5, CLass-150 RF (Drilled)

1.BS-1414/API-600

1. Body : 30 Bar (Hyd.)

2. Seat : 22 Bar (Hyd.)

BSEN 12266-1/ API-598

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid Wedge, SS 316 Trim Socket Welded Ends as Per ASME B-16.11

1.API-602/ EN-15761

1. Body 207 Bar (Hyd.)

2. Seat 152 Bar (Hyd.)

API-598/ BSEN-12266-1

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid Wedge, SS 304 Trim Socket Welded Ends as Per ASME B-16.11

1.API-602/ EN-15761

1. Body 207 Bar (Hyd.)

2. Seat 152 Bar (Hyd.)

API-598/ BSEN-12266-1

Screwed in Bonnet, O/S & Yoke Type, Rising Stem, Integral Seat , Solid Wedge Disc, Cu-Alloy Trim Flanged as per IS-778 Class-2 FF (Undrilled)

1.IS-778

1. Body : 2.4 MPa (Hyd.)

2. Seat : 1.6 MPa (Hyd.)

3. Max. working pressure : 1.6 MPa upto 45c

IS-778

Screwed in Bonnet, O/S & Yoke Type, Rising Stem, Integral Seat , Solid Wedge, Cu-Alloy Trim Screwed Female Threads to IS-554 (Parallel)

1.IS-778

1. Body : 2.4 MPa (Hyd.)

2. Seat : 1.6 MPa (Hyd.)

3. Max. Working Pressure : 1.6 MPa (Hyd.)

4. Max. Working Temp. : Upto 45C

IS-778

Screwed in Bonnet, O/S & Yoke Type, Rising Stem, Integral Seat , Solid Wedge, Cu-Alloy Trim Flanged as per IS-778 Class-1 FF(Undrilled)

1.IS-778

1. Body : 1.5 MPa (Hyd.)

2. Seat : 1.0 MPa (Hyd.)

3. Max. Working Pressure : 1.0 MPa (Hyd.)

4. Max. Working Temp. : Upto 45�C

IS-778

Screwed in Bonnet, O/S & Yoke Type, Rising Stem, Integral Seat, Solid Wedge, Cu-Alloy Trim Screwed Female Threads to IS-554 (Parallel)

1.IS-778

1. Body : 1.5 MPa (Hyd.)

2. Seat : 1.0 MPa (Hyd.)

3. Max. Working Pressure : 1.0 MPa (Hyd.)

4. Max. Working Temp. : Upto 45�C

IS-778

Screwed in Bonnet, Inside Screw, Non Rising Stem, Integral Seat, Solid Wedge, Cu-Alloy Trim Flanges as per IS-778 Class-2 FF (Undrilled)

1.IS-778

1. Body 2.4 MPa (Hyd.)

2. Seat 1.6 MPa (Hyd.)

3. Max. Working Pressure : 1.6 MPa (Hyd.)

4. Max. Working Temp. : Upto 45�C

IS-778

Screwed in bonnet, Inside screw, Non-Rising stem Screwed female ends as per IS 554

1.IS-778

1. Body : 2.4 MPa (Hyd.)

2. Seat & Back Seat : 1.6 MPa (Hyd.)

3. Working Pressure : 1.6 MPa Upto 45�C

IS-778

Screwed in Bonnet, Inside Screw, Rising Stem, Integral Seat, Solid Wedge, Cu-Alloy Trim Screwed Female Threads to IS-554 (Parallel)

1.IS-778

1. Body 2.4 MPa (Hyd.)

2. Seat 1.6 MPa (Hyd.)

IS-778

Screwed in bonnet, Inside screw, Non-Rising stem Flanged ends as per IS 778, Class 1

1.IS-778

1. Body : 1.5 MPa (Hyd.)

2. Seat : 1.0 MPa (Hyd.)

3. Max. Working Pressure : 1.0 MPa (Hyd.)

4. Max. Working Temp. : Upto 45�C

IS-778

Screwed in Bonnet, Inside Screw, Non Rising Stem, Integral Seat, Solid Wedge, Cu-Alloy Trim Screwed ends as per IS-554

1.IS-778

1. Body 1.5 MPa (Hyd.)

2. Seat 1.0 MPa (Hyd.)

3. Max. Working Pressure : 1.0 MPa (Hyd.)

4. Max. Working Temp. : Upto 45�C

IS-778

Screwed in bonnet, Inside screw, Non-Rising stem, Integral seat, Solid Wedge Screwed female BSP parallel threads as per BS-21

1. Body : 350 Psi g (Hyd.)

2. Seat : 255 Psi g (Hyd.)

Screwed in bonnet, Inside screw, Non-Rising stem, With locking arrangement & position indicator, handwheel operated Flanged ends as per BS-10, Table-D

1. Body : 300 Psi g (Hyd.)

2. Seat : 200 Psi g (Hyd.)

Screwed in Bonnet, Inside Screw,Non Rising Steam Hand Wheel Operated, Integral Seat, Cu-Alloy Trim, Open Shut Indicator, Locking Arrangement One Side Flange end to BS-10 Table-D, Other Side end BSP Parallel threads to BS-21

1. Body : 300 Psi g (Hyd.)

2. Seat : 200 Psi g (Hyd.)

Screwed in bonnet, Inside screw, Non-Rising stem, Integral Seat, Split (Double) Wedge Screwed ends BSP parallel threads as per BS-21

1. Body : 348 Psi g (Hyd.)

2. Seat : 255 Psi g (Hyd.)

3. Max. Working Pressure : 232 Psi g (Hyd.)

Screwed in bonnet, Inside screw, Non-Rising stem Flanged ends to BS-10 Table-D (Undrilled)

1. Body : 348 Psi g (Hyd.)

2. Seat : 255 Psi g (Hyd.)

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Renewable Plug Type Disc , SS 316 Trim Flanges as per ASME B16.5, Class-600 RF (Drilled)

1. BS-1873

1. Body : 153 Bar (Hyd.)

2. Seat : 112 Bar (Hyd.)

1. BSEN-12266-1

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Renewable Plug Type Disc , SS 304 Trim Flanges as per ASME B16.5, Class-600 RF (Drilled)

1. BS-1873

1. Body : 153 Bar (Hyd.)

2. Seat : 112 Bar (Hyd.)

1. BSEN-12266-1

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Renewable Plug Type Disc , SS Trim Flanges as per ASME B16.5, Class-600 RF (Drilled)

1. BS-1873

1. Body : 153 Bar (Hyd.)

2. Seat : 112 Bar (Hyd.)

1. BSEN-12266-1

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid or Flexible Wedge , SS 316 Trim Flanges as per ASME B16.5, CLass-300 RF (Drilled)

1. BS-1873

1. Body : 76 Bar (Hyd.)

2. Seat : 55 Bar (Hyd.)

1. BSEN-12266 Part-1

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat & Plug Type Disc, SS 304 Trim Screwed Female NPT Threads as per ASME B1.20.1

1. API-602/ BSEN-15761

1. Body : 207 Bar (Hyd.)

2. Seat : 152 Bar (Hyd.)

1. API-598/ BSEN-12266-1

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat & Plug Type Disc, SS 316 Trim Screwed Female NPT Threads as per ASME B1.20.1

1. API-602/ BSEN-15761

1. Body : 207 Bar (Hyd.)

2. Seat : 152 Bar (Hyd.)

1. API-598/ BSEN-12266-1

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat & Plug Type Disc, SS Trim Screwed Female NPT Threads as per ASME B1.20.1 .

1. API-602/ BSEN-15761

1. Body : 207 Bar (Hyd.)

2. Seat : 152 Bar (Hyd.)

1. API-598/ BSEN-12266-1

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat & Plug Type Disc, SS Trim Socket Welded Ends as Per ASME B-16.11

1. API-602/ BSEN-15761

1. Body : 207 Bar (Hyd.)

2. Seat : 152 Bar (Hyd.)

1. API-598/ BSEN-12266-1

Standard Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Plug Type Disc, SS 316 Trim Socket Welded Ends as per ASME B-16.11

1. API-602/EN-15761

1. Body : 384 Bar (Hyd.)

2. Seat : 281 Bar (Hyd.)

1. BSEN-12266-1

Standard Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Plug Type Disc, SS 304 Trim Socket Welded Ends as per ASME B-16.11

1. API-602/EN-15761

1. Body : 384 Bar (Hyd.)

2. Seat : 281 Bar (Hyd.)

1. BSEN-12266-1

Standard Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Plug Type Disc, SS Trim Socket Welded Ends as per ASME B-16.11

1. API-602/EN-15761

1. Body : 384 Bar (Hyd.)

2. Seat : 281 Bar (Hyd.)

1. BSEN-12266-1

Standard Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Renewable Plug Type Disc, SS Trim Flanges as per ASME B 16.5 CL-600 R.F. (Drilled)

1. API-602/EN-15761

1. Body : 153 Bar (Hyd.)

2. Seat : 112 Bar (Hyd.)

1. API-598/ BSEN-12266-1

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat & Plug Type Disc, SS 316 Trim Socket Welded Ends as Per ASME B-16.11

1. API-602/ BSEN-15761

1. Body : 207 Bar (Hyd.)

2. Seat : 152 Bar (Hyd.)

1. API-598/ BSEN-12266-1

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat & Plug Type Disc, SS 304 Trim Socket Welded Ends as Per ASME B-16.11

1. API-602/ BSEN-15761

1. Body : 207 Bar (Hyd.)

2. Seat : 152 Bar (Hyd.)

1. API-598/ BSEN-12266-1

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid or Flexible Wedge , SS 304 Trim Flanges as per ASME B16.5, CLass-300 RF (Drilled)

1. BS-1873

1. Body : 76 Bar (Hyd.)

2. Seat : 55 Bar (Hyd.)

1. BSEN-12266 Part-1

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Solid or Flexible Wedge , SS Trim, Flanges as per ASME B16.5, CLass-300 RF (Drilled)

1. BS-1873

1. Body : 76 Bar (Hyd.)

2. Seat : 55 Bar (Hyd.)

1. BSEN-12266 Part-1

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Renewable Plug Type Disc , SS 316 Trim Flanges as per ASME B16.5, Class-150 RF (Drilled)

1. BS-1873

1. Body : 30 Bar (Hyd.)

2. Seat : 22 Bar (Hyd.)

1. BSEN-12266-1

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Renewable Plug Type Disc , SS 304 Trim Flanges as per ASME B16.5, Class-150 RF (Drilled)

1. BS-1873

1. Body : 30 Bar (Hyd.)

2. Seat : 22 Bar (Hyd.)

1. BSEN-12266-1

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Renewable Plug Type Disc , SS Trim Flanges as per ASME B16.5, Class-150 RF (Drilled)

1. BS-1873

1. Body : 30 Bar (Hyd.)

2. Seat : 22 Bar (Hyd.)

1. BSEN-12266-1

Bolted Bonnet, O/S & Yoke Type, Renewable Seat & Disc, SS Trim Flanged Ends as per BSEN 1092-1, RF PN-40 (Drilled)

1. BSEN-13709

1. Body : 60 Bar (Hyd.)

2. Seat : 40 Bar (Hyd.)

Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat & Flat Disc Flanged Ends as per BSEN 1092-1, PN-40.

1. BSEN-13709:02 (BS-5160)

1. Body : 60 Bar (Hyd.)

2. Seat : 40 Bar (Hyd.)

1. BSEN-12266 Part-1

Screwed in Bonnet, O/S & Yoke Type, Rising Stem, Integral Seat , Renewable Disc, Cu-Alloy Trim Flanges as per IS-778 Class-2 FF (Undrilled)

1. IS-778

1. Body : 2.4 MPa (Hyd.)

2. Seat : 1.6 MPa (Hyd.)

3. Max. working pressure : 1.6 Mpa upto 45�C

1. IS-778

Screwed in Bonnet, O/S & Yoke Type, Rising Stem, Integral Seat , Renewable Disc, Cu-Alloy Trim Screwed Female Threads to IS-554 (Parallel)

1. IS-778

1. Body : 2.4 MPa (Hyd.)

2. Seat : 1.6 MPa (Hyd.)

3. Max. working pressure : 1.6 Mpa upto 45�C

1. IS-778

Screwed in Bonnet, O/S & Yoke Type, Rising Stem, Integral Seat , Renewable Disc, Cu-Alloy Trim Flanges as per IS-778 Class-1 FF (Undrilled)

1. IS-778

1. Body : 1.5 MPa (Hyd.)

2. Seat : 1.0 MPa (Hyd.)

3. Max. Working Pressure : 1.0 MPa (Hyd.)

4. Max. Working Temp. : Upto 45�C

1. IS-778

Screwed in Bonnet, O/S & Yoke Type, Rising Stem, Integral Seat , Renewable Disc, Cu-Alloy Trim Screwed Female Threads to IS-554(Parallel)

1. IS-778

1. Body : 1.5 MPa (Hyd.)

2. Seat : 1.0 MPa (Hyd.)

3. Max. Working Pressure : 1.0 Mpa upto 45�C

1. IS-778

Screwed in Bonnet, Inside Screw, Rising Stem, Integral Seat, Renewable Disc, Cu-Alloy Trim Flanges as per IS-778 Class-2 FF (Undrilled)

1. IS-778

1. Body : 2.4 MPa (Hyd.)

2. Seat : 1.6 MPa (Hyd.)

3. Max. Working Pressure : 1.6 MPa (Hyd.)

4. Max. Working Temp. : Upto 45�C

1. IS-778

Screwed in Bonnet, Inside Screw, Rising Stem, Integral Seat, Renewable Disc, Cu-Alloy Trim Screwed Female Threads to IS-554 (Parallel)

1. IS-778

1. Body : 1.5 MPa (Hyd.)

2. Seat : 1.0 MPa (Hyd.)

3. Max. Working Pressure : 1.0 MPa (Hyd.)

4. Max. Working Temp. : Upto 45�C

1. IS-778

Screwed in bonnet, Inside screw, Rising stem, Integral Seat, Plug type disc Flanged ends

1. IS-778

1. Body : 1.5 MPa (Hyd.)

2. Seat : 1.0 MPa (Hyd.)

3. Max. Working Pressure : 1.0 MPa (Hyd.)

4. Max. Working Temp. : Upto 45�C

1. IS-778

Screwed in Bonnet, Inside Screw, Rising Stem, Hand Wheel Operated, Integral Seat, Renewable Disc, Cu-Alloy Trim Flanges as per BS � 10 Table-D (Undrilled)

1. Body : 300 Psi g (Hyd.)

2. Seat : 200 Psi g (Hyd.)

Screwed in Bonnet, Inside Screw,Non Rising Steam Hand Wheel Operated, Integral Seat, Cu-Alloy Trim, Open Shut Indicator, Locking Arrangement One Side Flange end to BS-10 Table-D, Other Side end BSP Parallel threads to BS-21

1. Body : 300 Psi g (Hyd.)

2. Seat : 200 Psi g (Hyd.)

Screwed in Bonnet, Inside Screw, Rising Stem, Renewable Seat (Teflon), Cu-Alloy Trim Screwed Female BSP Parallel Threads (BS-21)

1. Body : 500 Psi g (Hyd.)

2. Seat : 250 Psi g (Hyd.), 100 Psi g (Air)

Screwed in Bonnet, Inside Screw, Rising Stem, Integral Seat, Cu-Alloy Trim Flanged Ends to BS-10 Table-D (Undrilled)

1. Body : 348 Psi g (Hyd.)

2. Seat : 255 Psi g (Hyd.)

Screwed in Bonnet, Inside Screw, Rising Stem, Integral Seat, Cu-Alloy Trim Screwed Female BSP Parallel Threads to BS-21

1. BS 5154

1. Body : 348 Psi g (Hyd.)

2. Seat : 256 Psi g (Hyd.)

Screwed in bonnet, Inside screw, Rising stem, Integral seat Screwed female BSP parallel threads to BS-21

1. BS 5154

1. Body : 450 Psi g (Hyd.)

2. Seat & Back Seat : 320 Psi g (Hyd.)

3. Max. Working Pressure : 290 Psi g (Hyd.)

4. Max. Working Temp. : 200C

Union bonnet, Inside screw, Rising stem, S.S. trim, Renewable seat/disc Flanged ends BS-10 Table-F

1. BS 5154

1. Body : 450 Psi g (Hyd.)

2. Seat & Back Seat : 320 Psi g (Hyd.)

3. Max. Working Pressure : 290 Psi g (Hyd.)

4. Max. Working Temp. : 200C

1. BS 5154

Union bonnet, Inside screw, Rising stem, S.S. trim, Renewable seat & disc Screwed female BSP parallel threads to BS-21 , Class-150 / PN-20 Gun Metal (EN-1982 Gr. CC 491K)

1. BS 5154

1. Body : 450 Psi g (Hyd.)

2. Seat & Back Seat : 320 Psi g (Hyd.)

3. Max. Working Pressure : 290 Psi g (Hyd.)

4. Max. Working Temp. : 200C

1. BS 5154

Horizontal Type Flanges as per BS-10 Table-FF (Undrilled)

1. 300 Psi g Hyd.

2. Max. B.O.P. : 150 Psi g (Steam)

3. Max. Working Temp. : 220C

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Renewable Needle Type Disc, SS 316 Trim Socket Welded Ends as per ASME B-16.11

1. API-602/EN-15761

1. Body : 207 Bar (Hyd.)

2. Seat : 152 Bar (Hyd.)

1. BSEN-12266-1

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Renewable Needle Type Disc, SS 304 Trim Socket Welded Ends as per ASME B-16.11

1. API-602/EN-15761

1. Body : 207 Bar (Hyd.)

2. Seat : 152 Bar (Hyd.)

1. BSEN-12266-1

Reduced Bore, Bolted Bonnet, O/S & Yoke Type, Rising Stem, Renewable Seat, Renewable Needle Type Disc, SS Trim Socket Welded Ends as per ASME B-16.11

1. API-602/EN-15761

1. Body : 207 Bar (Hyd.)

2. Seat : 152 Bar (Hyd.)

1. BSEN-12266-1

One Piece Design, Reduced Bore, Renewable Needle Type Disc, SS Trim, Screwed Female NPT Threads as per ASME B1.20.1

1. API-602

1. Body : 207 Bar (Hyd.)

2. Seat : 152 Bar (Hyd.)

1. API-598

Screwed in bonnet, Inside screw, Rising stem, Integral seat Screwed female BSP parallel threads to BS-21

1. Body : 300 Psi g (Hyd.)

2. Seat : 150 Psi g (Hyd.)

Flanged ends to BS-10, Table-H

1. Body : 500 Psi g (Hyd.)

2. Working Pressure : 250 Psi g (Steam)

3. Max. Working Temp. : 225C

Rack and Pinion Operated with key, Renewable Seat & Disc, SS Trim Flanges as per BS-10 Table-J FF (Undrilled)

1. Body : 700 Psi g (Hyd.)

2. Max. B.O.P. : 350 Psi g at 400C

Fitted with Taper Plug in a Tapper Seated Body Screwed Female BSP Parallel Threads (BS-21)

1. Body : 200 Psi g (Hyd.)

2. Seat : 100 Psi g (Hyd.)

Fitted with Taper Plug in a Tapper Seated Body Flanged Ends to BS-10 Table-D (Undrilled)

1. Body : 300 Psi g (Hyd.)

2. Seat : 150 Psi g (Hyd.)

Pilot Operated Outlet Pressure Range Available 5/45, 40/100 & 90/150 Psi g, Renewable Seat

1. 300 Psi g (Hyd.)

2. Max working pressure : 150 Psi g (Steam)

3. Max. working temp. : 220C

Spring Loaded, Outlet Pressure Range Available 5/60, 20/80 & 40/125 PSIG, Cu-Alloy Trim Screwed Female BSP Taper Threads(BS-21)

1. Body : 500 Psi g (Hyd.)

2. Max. B.O.P. : 250 Psi g

Pilot Operated Outlet Pressure Range Available 5/45, 40/125 Psi g (Steam), Renewable Seat, SS Trim Flanges as per BS-10 Table-FF (Undrilled)

1. Body : 300 (Hyd.)

1. 150 Psi g (Steam)

Compact size, Piston type Screwed female BSP threads to BS-21

1. Max. Working Temp. : 80C

2. Max. Upstream Pressure : 25 Bar

1. Pressure at Max. Inlet Pressure : Min. : 0.8 bar, Max. : 5.5 Bar

1. 25kg/cm g (Hyd.)

Spring Loaded, Full Lift, Renewable Seat & Disc Inlet Flanged to BS-10 Table-FF (Undrilled), Outlet Flanged to BS-10 Table-D FF (Undrilled)

1. 300 Psi g (Hyd.)

2. Max. set pressure : 150 Psi g (Steam)

Spring Loaded, High Lift, Renewable Seat & Disc Inlet Flanged to BS-10 Table-FF (Undrilled), Outlet Flanged to BS-10 Table-D FF (Undrilled)

1. 300 Psi g (Hyd.)

2. Max. set Pressure : 150 Psi g (Steam)

3. Max. Working Temp. : 220C

Spring Loaded, High Lift, Renewable Seat & Disc Inlet Flanged to BS-10 Table-FF (Undrilled) Outlet Flanged to BS-10 Table-D FF (Undrilled)

1. 300 Psi g (Hyd.)

2. Max. set pressure : 150 Psi g (Steam)

3. Working Temp. : 220C

Pop Type, Spring Loaded, Enclosed Discharge, Right Angle, Cu-Alloy Trim Flanges as per BS-10 Table-H FF (Undrilled)

1. Body : 500 Psi g (Hyd.)

2. Max. set pressure : 250 Psi g

3. Max. working temp. : 220C

Pop Type, Spring Loaded, Enclosed Discharge, Right Angle, Cu-Alloy Trim Inlet Screwed Male BSP Taper Threads (BS-21), Outlet Screwed Female BSP Parallel Threads (BS-21)

1. Body : 500 Psi g (Hyd.)

2. Max. set pressure : 250 Psi g

3. Max. working temp. : 220C

Pop Type, Spring Loaded, Open Discharge, Cu-Alloy Trim Flanges as per BS-10 Table-H FF (Undrilled)

1. Body : 500 Psi g (Hyd.)

2. Max. Set pressure : 250 Psi g

3. Max. working temp. : 220C

Pop Type, Spring Loaded, Open Discharge, Cu-Alloy Trim Inlet Screwed Male BSP Taper Threads (BS-21)

1. Body : 500 Psi g (Hyd.)

2. Max. B.O.P. : 250 Psi g

3. Max. working temp. : 220C

Open discharge, Spring Loaded Screwed male BSP taper threads as per BS-21

1. Body : 300 Psi g (Hyd.)

2. Max. Set Pressure : 150 Psi g

3. Max. Working Temp. : 220C

Enclosed discharge Flanges as per BS-10, Table-F (Undrilled)

1. Body : 300 Psi g (Hyd.)

2. Max. Set Pressure : 150 Psi g

3. Max. Working Temp. : 220C

Enclosed discharge Inlet Screwed male BSP taper threads as per BS-21

1. Body : 300 Psi g (Hyd.)

2. Max. Set Pressure : 150 Psi g

3. Max. Working Temp. : 220C

Spring Loaded, Full Lift, Renewable Seat & Disc, SS Trim Inlet Flanged to ASME B16.5 Class-300

1. Body : 700 Psi g (Hyd.)

2. Set Pressure : Max. 350 Psi g

Spring Loaded, Full Lift, Renewable Seat & Disc, SS Trim Inlet Flange to BS-10 Table-H FF (Undrilled), Outlet Flanged to BS-10 Table-D FF (Undrilled)

1. Body : 500 Psi g (Hyd.)

2. Max. Set Pressure : 250 Psi g

3. Max. Working Temp. : 400C

Spring Loaded, High Lift, Renewable Seat & Disc Inlet Flange to BS-10 Table-H FF (Undrilled), Outlet Flanged to BS-10 Table-D (Undrilled)

1. Body : 500 Psi g (Hyd.)

2. Max. Working Pressure : 250 Psi g (Steam)

3. Max. Working Temp. : 400C

Spring Loaded, High Lift, Renewable Seat & Disc Inlet Flange to BS-10 Table-H F/F (Undrilled), Outlet Flanged to BS-10 Table-D FF (Undrilled)

1. Body : 500 Psi g (Hyd.)

2. Max. Working Pressure : 250 Psi g (Steam)

3. Max. Working Temp. : 400C

BSP taper threads as per BS-21

1. Body : 500 Psi g (Hyd.)

2. Max. BOP Working Pressure : 250 Psi g (Steam)

3. Max. Working Temp. : 220C

Single window with toughened glass & moving impeller Screwed female BSP parallel threads to BS-21

1. 150 Psi g (Hyd.)

Single window with toughened glass Screwed female ends to BS-21

1. BS 5154

1. Body : 300 Psi g (Hyd.)

Bolted Bonnet, Outside Screw & Yoke Type, Rising Stem with Backseat Arrangement, Renewable Seat & Disc, SS Trim Flanges as per BSEN 1092-2 (PN-16)

1. Body : 24kg/cm2 (348 Psi g) Hyd.

2. Seat : 17.6kg/cm2 (255 Psi g) Hyd.

Bolted Bonnet, Outside Screw & Yoke Type, Rising Stem with Backseat Arrangement, Renewable Seat & Disc, S.S. Trim Flanged as per BSEN 1092-2 PN-10

1. Body : 16kg/cm2 (230 Psi g) Hyd.

2. Seat : 10kg/cm2 (159 Psi g) Hyd.

Bolted Bonnet, Outside Screw & Yoke Type, Rising Stem with Backseat Arrangement, Renewable Seat & Disc, SS Trim Flanges as per BSEN 1092-2 PN-16

1. Body : 24kg/cm2 (348 Psi g) Hyd.

2. Seat : 17.6kg/cm2 (255 Psi g) Hyd.

S.G. Iron material available on customer request.

Outside Screw, Yoke Type, Rising Stem, Screwed in Bonnet/ Bolted Bonnet,Renewable Seat & Disc, SS Trim Flanges as per BS-10 Table-F FF (Undrilled)

1. Body : 500 Psi g (Hyd.)

2. Max. steam working pressure : 250 Psi g

Outside Screwed, Yoke Type, Rising Stem, Screwed in Bonnet/ Bolted Bonnet,Renewable Seat & Disc, SS Trim Flanges as per BS-10 Table-H FF (Undrilled)

1. Body : 500 Psi g (Hyd.)

2. Max. Steam working pressure : 250 Psi g

Outside Screw, Yoke Type, Rising Stem, Renewable Seat & Disc, SS Trim Screwed Female BSP Taper Threads (BS-21)

1. 500 Psi g (Hyd.)

2. Max. Steam working pressure : 250 Psi g

Screwed in Bonnet, Inside Screw, Rising Stem, Renewable Seat & Disc, SS Trim Flanges as per BS-10 Table-F FF (Undrilled)

1. 300 Psi g (Hyd.)

2. Max. Steam working pressure : 150 Psi g

Screwed in Bonnet, Inside Screw, Rising Stem, Renewable Seat & Disc, SS Trim Flanges as per BS-10 Table-H FF (Undrilled)

1. 500 Psi g (Hyd.)

2. Max. Steam working pressure : 250 Psi g

Screwed in Bonnet, Inside Screw, Rising Stem, Renewable Seat & Disc, SS Trim Screwed Female BSP Taper Threads (BS-21)

1. Body : 500 Psi g (Hyd.)

2. Max. Steam working pressure : 250 Psi g

Screwed in Bonnet ,Inside Screw,Rising Stem ,S.S. trim, Renewable seat & disc Screwed female BSP parallel threads to BS-21

1. BS 5154

1. Body : 500 Psi g (Hyd.)

2. Seat : 250 Psi g (Hyd.)

Thermodynamic Type with in-built Strainer, SS Trim Screwed Female BSP Taper Threads (BS-21) or Socket Welded End as per ASME B16.11

1. Body : 900 Psi g (Hyd.)

2. Max. steam working pressure : 450 Psi g

Horizontal Type, Side Inlet Side Outlet, SS working parts Screwed Female BSP Parallel Threads to (BS-21)

1. Body : 300 Psi g (Hyd.)

2. Max. steam working pressure : 450 Psi g

Renewable S.S. working parts

1. 300 Psi g (Hyd.)

2. Working pressure suitable saturated steam upto 150 Psi g

With SS 304 Strainer Screwed Female BSP Taper Threads (BS-21)

1. 500 Psi g (Hyd.)

2. Max. B.O.P. : 250 Psi g (Steam)

3. Max. working temp. : 225C

Thermodynamic Type with Inbuilt Strainer, S.S. Trim Screwed female BSP parallel threads to BS-21

1. Body : 500 Psi g (Hyd.)

2. Max. Steam working pressure : 250 Psi g at 225�C

Thermodynamic Type with in-built Strainer, SS Trim Screwed Female BSP Parallel Threads (BS-21)

1. Body : 900 Psi g (Hyd.), 450 Psi g (Steam)

Y Type, Screwed in Cover, SS Screen Having 1mm Dia. Perforations Screwed Female BSP Parallel Threads (BS-21)

1. 500 Psi g (Hyd.)

2. Max. Steam working pressure : 250 Psi g

Bolted Cover,-Y Type, Renewable Seat Flanged End as per BS-10 Table-J FF (Undrilled)

1. Body : 700 Psi g (Hyd.)

2. Max. Working Pressure : 350 Psi g (Steam)

3. Max. Working Temp. : Upto 400C

Y Type, Screwed in Cover, SS Trim Flanges as per BS:10 Table-H FF (Undrilled)

1. Body : 500 Psi g (Hyd.)

2. Max. Steam working pressure : 250 Psi g

�Y� Type, Bolted Cover, SS Trim Flanges as per BS-10 Table-D FF (Drilled)

1. Tested to 10kg/cm2g

S.S. Screen with 1mm Dia. Perforations Screwed female BSP parallel threads to BS-21

1. Body : 300 Psi g (Hyd.)

2. Max. Working Pressure : 150 Psi g (Hyd.)

3. Max. Working Temp. : 200C