L&T Ball Valves are available in single-piece, two-piece and three-piece constructions. In these valves, line pressure forces the floating ball against the downstream seat to effect bubble-tight sealing.

Blowout Proof Stem. The side-entry stem of L&T Ball Valves has a shoulder that bears against a matching shoulder in the body to make it blowout proof - the higher the line pressure, the better the sealing to atmosphere.

High Integrity Stem Sealing. Sealing to atmosphere is further enhanced by stem thrust seals and stem packing rings. To compensate for wear and thermal expansions, Belleville springs are used.

Mirror-finished Solid Stainless Steel Balls. To obtain bubble-tight sealing and lower operating torques, mirror-finished SS balls are used as a standard. The solid construction of the balls guarantees higher structural strength.

Seats with Pressure-relieving Slots. Seats with fine grain structure are used to ensure better strength and longer life. Pressure-relieving slots are a unique feature of L&T Ball Valves. The slots relieve upstream pressure when the valve is in closed position and prevent seat damage.

Actuator Mounting Flange. L&T single-piece and two-piece Ball Valves are provided with an integral actuator mounting flange conforming to ISO 5211. Please note that full bore valves in sizes DN 15 to DN 25 would be supplied with mounting arrangement as per L&T's manufacturing standard.

Fire-Safe Feature. L&T fire-safe Ball Valves feature secondary metal seats. In the event of a fire, after the soft-seat totally sublimates, the ball moves and abuts the downstream metal seat to form a leak-tight seal.

Cavity Pressure Relief Mechanism. A slight increase in temperature of fluid entrapped in ball cavity can cause a rapid increase of pressure and damage the ball and seats. To prevent this, L&T Ball Valves are equipped with automatic cavity relief mechanisms. When the valve is in open position, a hole provided on the ball connects the body cavity to the ball port and thereby ensure that cavity pressure does not build up. In the closed condition, when the cavity pressure rises above a designated level, the seat lip deflects to relieve pressure to the upstream side.

Antistatic Feature. Static electricity builds up inside a valve when the ball rubs against non-metallic seats. This is a fire hazard, especially in flammable fluid pipelines. L&T Ball Valves have inbuilt antistatic mechanisms to provide electrical continuity. Stems of full bore valves of size 65 mm and above and regular bore valves of size 80 mm and above are equipped with spring-loaded plungers. In valves of smaller sizes, electrical continuity is achieved by using Carbon-filled PTFE thrust seal and graphite stem packings.

On-line Service. Three-piece Ball Valves are designed for easy on-line service. To access the valve internals, remove three connector bolts and swing the body out using the fourth bolt as a pivot.

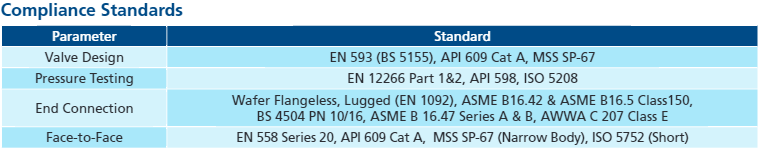

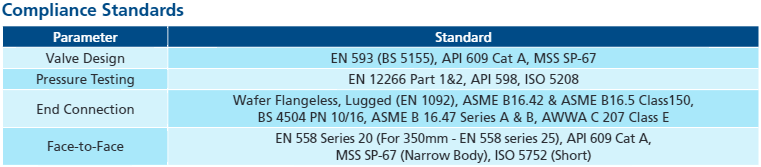

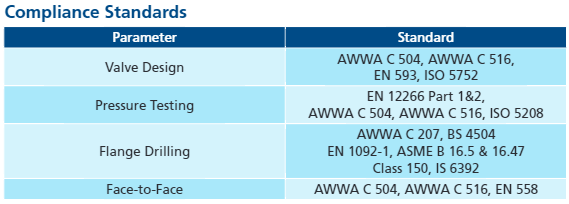

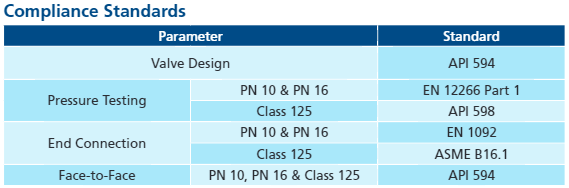

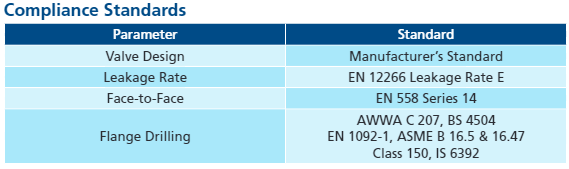

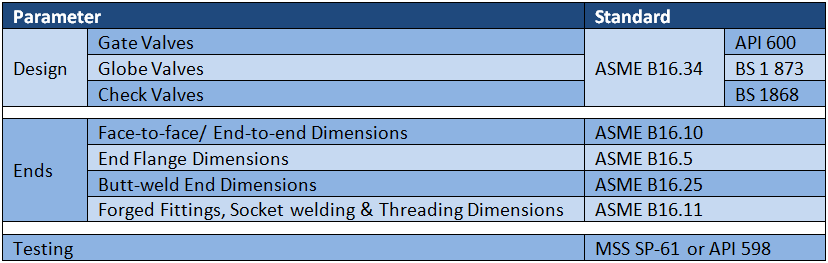

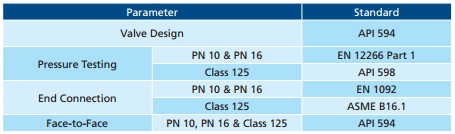

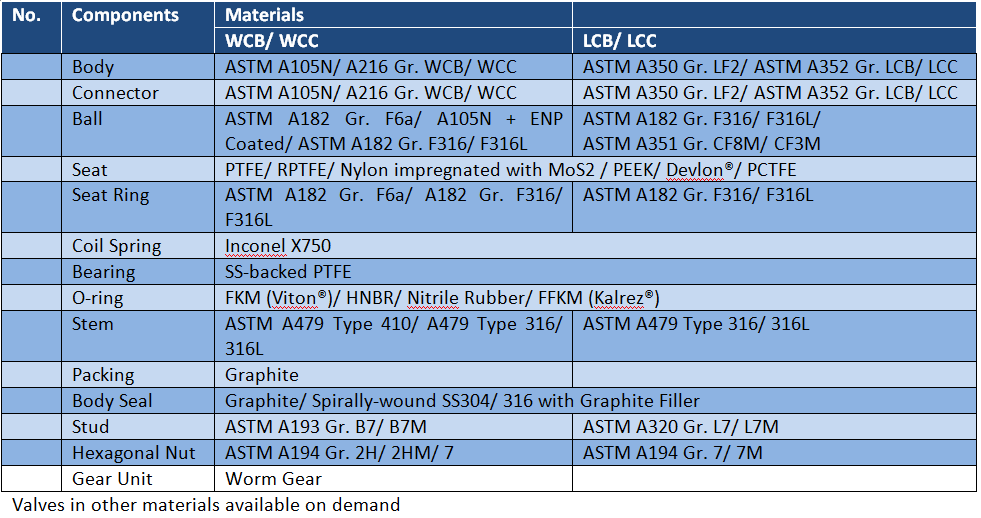

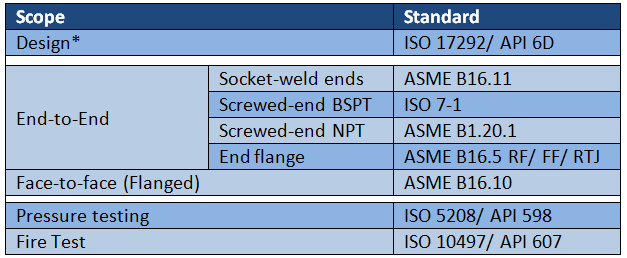

Standards

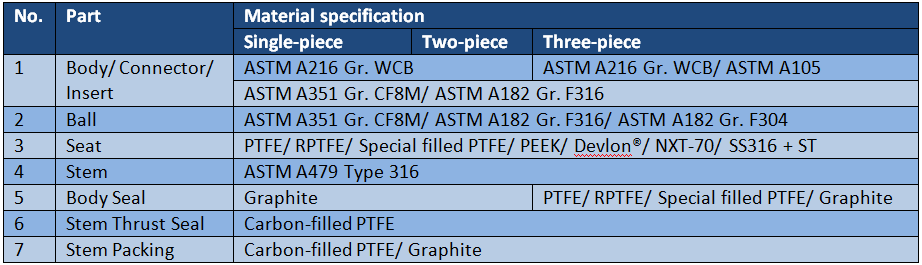

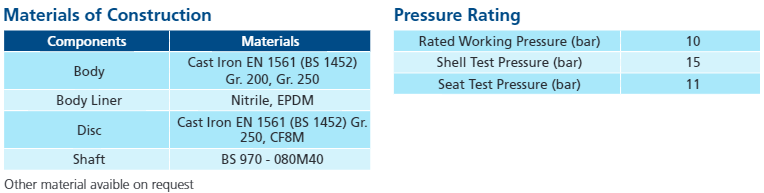

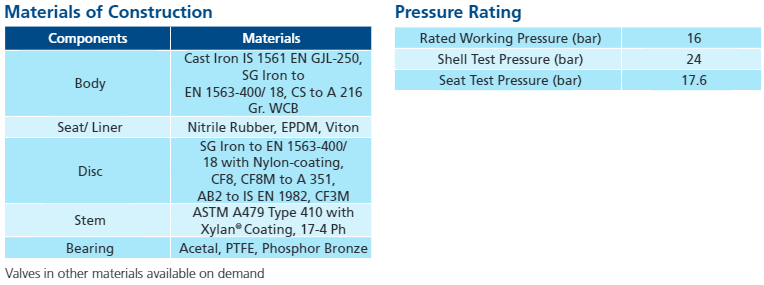

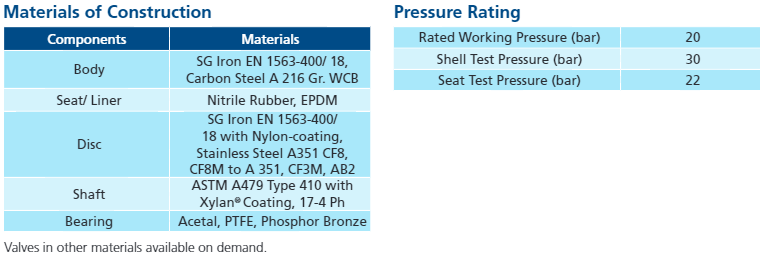

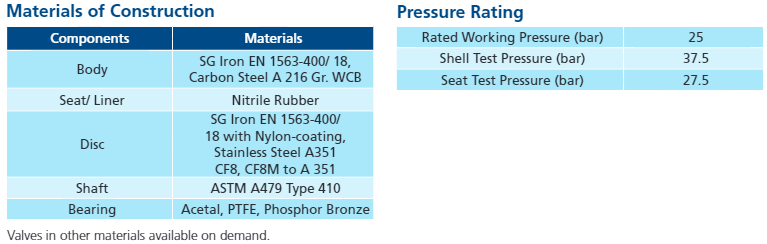

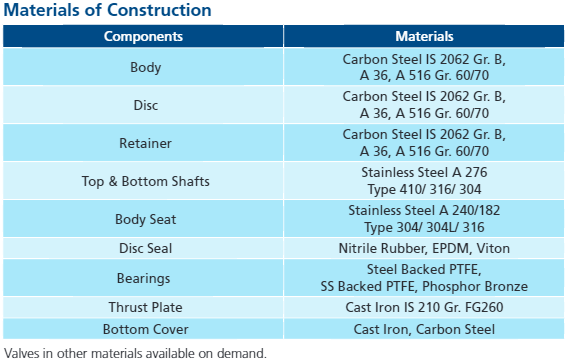

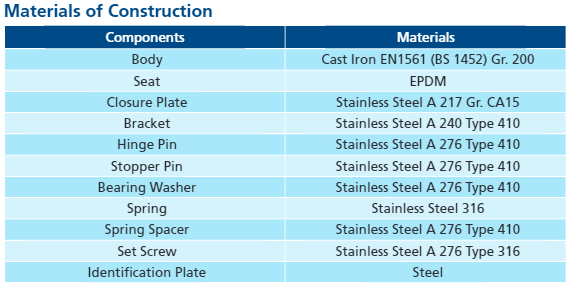

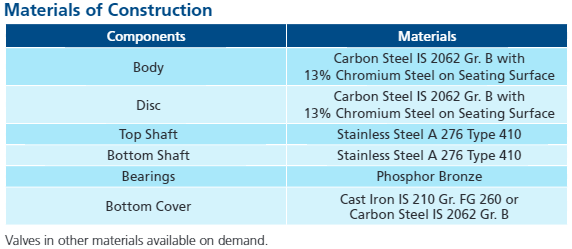

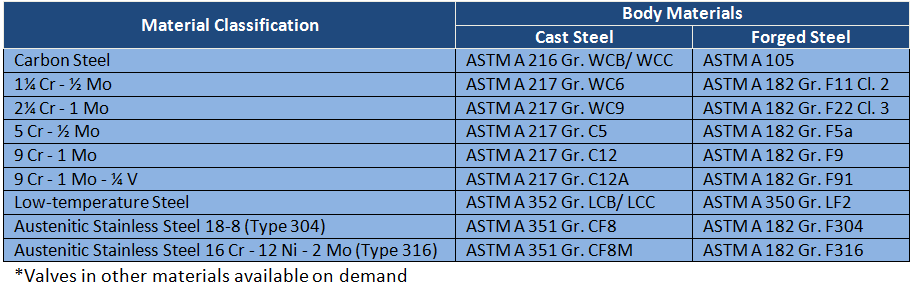

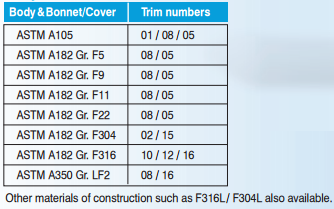

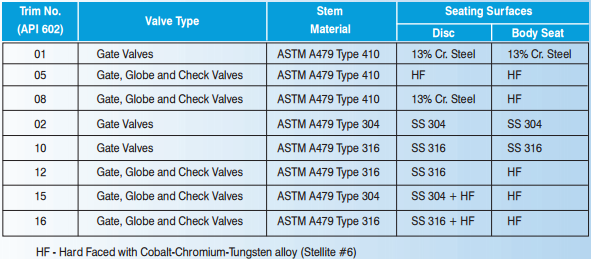

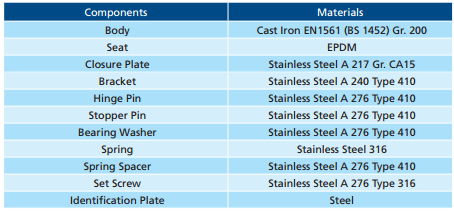

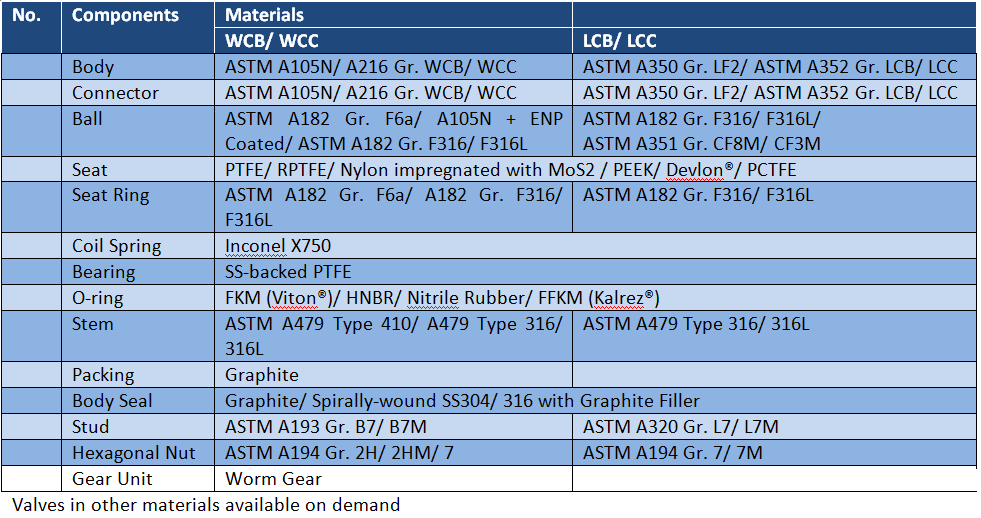

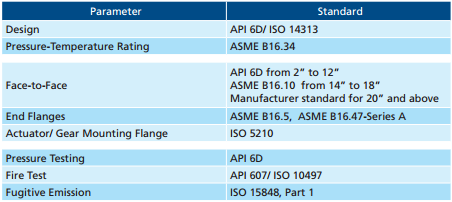

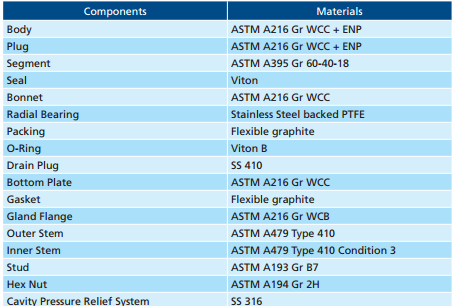

Material of Construction